How Air Cooled Screw Chillers Can Benefit Your Business

By:Admin

Introduction:

In today's rapidly evolving industrial landscape, the efficient management of temperature and humidity is paramount. To address this need, an industry-leading company, renowned for its pioneering spirit, has unveiled its latest groundbreaking solution – the Air-Cooled Screw Chiller*. This advanced cooling system is set to transform the way industries approach temperature control, offering unmatched performance, sustainability, and reliability.

*For the purpose of this article, the brand name of the Air-Cooled Screw Chiller will be excluded.

Unleashing Unmatched Performance:

Embracing cutting-edge technology, the Air-Cooled Screw Chiller represents the pinnacle of cooling innovation. Its screw compressors utilize a unique design, enabling them to deliver significantly higher energy efficiency levels compared to traditional cooling systems. By doing so, this chiller minimizes energy consumption while maximizing cooling output for industrial applications of any scale.

An Unrivaled Cooling Solution:

By opting for an air-cooled design, this innovative chiller eliminates the constraints posed by water availability and environmental factors. The necessity for water-cooling towers and the associated infrastructure is replaced by a self-contained system that effortlessly cools the surrounding air. This environmentally friendly approach not only reduces water consumption but also simplifies installation and maintenance processes, saving valuable time and resources.

Smart Control and Monitoring:

Equipped with advanced control systems, the Air-Cooled Screw Chiller optimizes performance through a combination of intelligent algorithms and precise temperature monitoring capabilities. This enhanced control functionality ensures consistent cooling, adapts to varying load demands, and provides real-time data for efficient management. Beyond this, the chiller can be seamlessly integrated into existing facility management systems, enabling remote monitoring and control for unparalleled convenience.

Enhanced Reliability and Durability:

The robust design of the Air-Cooled Screw Chiller is purpose-built to withstand the harshest operating conditions. Quality materials and stringent manufacturing processes ensure the system's ability to sustain robust performance over time. This reliable and durable cooling solution guarantees reduced downtime and maintenance costs, giving industries the peace of mind to focus on their core operations.

Sustainability at the Core:

Recognizing the global shift towards sustainability, the Air-Cooled Screw Chiller incorporates numerous environmentally conscious features. By eliminating the need for cooling towers and minimizing refrigerant leakages, this chiller significantly reduces the emission of harmful greenhouse gases. Additionally, the system's energy efficiency helps industries lower their carbon footprint, contributing to a greener future.

Applications Across Industries:

The versatility of the Air-Cooled Screw Chiller makes it an ideal solution for a wide range of industries. From data centers and manufacturing units to commercial buildings and healthcare facilities, this chiller can effectively meet the cooling needs of diversified sectors. Its adaptability ensures optimum performance in challenging conditions while maintaining superior efficiency.

Conclusion:

In an age where efficient cooling solutions are integral to industrial success, the Air-Cooled Screw Chiller emerges as a game-changer. By introducing next-generation technology, this innovative system surpasses traditional cooling methods by combining exceptional performance, sustainability, and reliability. As industries increasingly prioritize energy efficiency, this chiller offers a reliable and future-proof solution that supports their quest for operational excellence while minimizing environmental impact. Embrace the extraordinary and revolutionize your cooling requirements with the Air-Cooled Screw Chiller.

Company News & Blog

IQF Technology for Freezing Vegetables and Fruits - Preserving Freshness and Nutrients

Iqf Vegetable Fruit Freezer Focuses on Quality and EfficiencySpecializing in the production of IQF (Individual Quick Freezing) vegetable and fruit products, Iqf Vegetable Fruit Freezer has become a leading provider of high-quality frozen food products across the globe. Since its establishment, the company has prioritized quality and efficiency, ensuring that all products meet the highest standards of safety and quality.Established in 1998, Iqf Vegetable Fruit Freezer has grown substantially, expanding its product range and geographic reach over the years. Initially focused on the domestic market, the company soon began exporting to international markets, thanks in part to its reputation for quality and reliability. Today, Iqf Vegetable Fruit Freezer provides its products to customers in over 20 countries, including the United States, Europe, and Asia.One of the key factors driving the company's success is its focus on product quality. Iqf Vegetable Fruit Freezer uses only the freshest and highest-quality vegetables and fruits in its products, and adheres to strict quality and safety standards throughout the production process. This commitment to quality has earned the company numerous certifications, such as ISO 22000, HACCP, and BRC Global Standard for Food Safety.In addition to its focus on quality, Iqf Vegetable Fruit Freezer is also committed to efficiency and sustainability. The company has invested heavily in advanced freezing technology and equipment, enabling it to freeze products quickly and efficiently, while minimizing energy consumption and reducing waste. By utilizing advanced IQF technology, Iqf Vegetable Fruit Freezer ensures that its products retain their natural flavors, textures, and nutritional value, while maintaining their safety and quality.The company's commitment to sustainability extends beyond its production processes, as well. Iqf Vegetable Fruit Freezer sources its raw materials from local and international suppliers who share its commitment to sustainability and environmental stewardship. By working with suppliers who prioritize sustainable agriculture and responsible sourcing practices, Iqf Vegetable Fruit Freezer can minimize its environmental impact and ensure the long-term sustainability of its supply chain.In addition to its focus on quality and sustainability, Iqf Vegetable Fruit Freezer is also dedicated to customer satisfaction. The company employs a team of experienced professionals who work closely with customers to understand their needs and preferences, and to develop customized solutions that meet their specific requirements. From product development to order fulfillment and delivery, Iqf Vegetable Fruit Freezer is committed to providing its customers with exceptional service and support.With its focus on quality, efficiency, sustainability, and customer satisfaction, Iqf Vegetable Fruit Freezer has established itself as a leading provider of IQF vegetable and fruit products. As the demand for high-quality frozen food products continues to grow, the company is well-positioned to meet the needs of customers across the globe, thanks to its innovative approach to production and its commitment to excellence. Whether you're a food manufacturer, distributor, or retailer, Iqf Vegetable Fruit Freezer has the expertise, resources, and products you need to succeed.

Why Every Kitchen Needs a Reliable Ice Making Machine

Title: Cutting-Edge Ice Machine Technology Revolutionizing Commercial RefrigerationIntroduction:In a world where efficiency and reliability are paramount, one industry-leading company is at the forefront of developing cutting-edge ice machine technology. By combining innovation and advanced engineering, this company is revolutionizing the way commercial refrigeration works. With a focus on sustainability, energy efficiency, and optimal ice production, their ice machines are rapidly becoming an essential component in various industries. Let's delve deeper into their impressive portfolio and how they are reshaping the refrigeration landscape.1. Sustainability and Energy Efficiency:Recognizing the increasing urgency to reduce our carbon footprint, the company's ice machines employ state-of-the-art technologies to optimize energy consumption and minimize environmental impact. By utilizing advanced insulation materials, high-efficiency compressors, and intelligent control systems, their ice machines significantly reduce energy consumption while maintaining consistent ice production levels. This leads to lower operational costs and a more sustainable approach towards commercial refrigeration.2. Cutting-Edge Design and Engineering:The company's ice machines boast sleek, modern designs that seamlessly integrate into a variety of commercial environments. Their robust construction ensures durability, while ergonomic features facilitate easy maintenance and servicing. Utilizing advanced engineering techniques, these ice machines deliver supreme ice quality, whether in the form of cubed, crushed, or specialized ice shapes. The precise manufacturing process guarantees maximum ice clarity, density, and taste, meeting the stringent standards of diverse industries, from hospitality to healthcare.3. Automation and Smart Connectivity:Designed for efficiency and ease of management, the ice machines come equipped with smart connectivity features that enhance productivity. Real-time monitoring and diagnostics enable proactive maintenance, minimizing downtime and maximizing operational efficiency. Integrated smart sensors detect ice levels, ensuring a continuous supply without overproduction or wastage. Moreover, these machines can be seamlessly integrated into existing infrastructures, allowing for remote monitoring and control, facilitating better resource allocation for businesses.4. Versatility and Adaptability:Understanding the diverse needs of commercial establishments, the company's ice machines offer a range of customization options to suit specific requirements. With various size capacities, they cater to businesses of all scales, from boutique cafes to large-scale food production facilities. The machines are also capable of producing ice with varying thickness and consistency, adapting to different applications, such as cocktails, food preservation, or medical use. This versatility ensures that the ice machines can meet the specific needs of each industry, providing optimal performance and quality.5. Uncompromised Hygiene and Safety:Maintaining the highest standards of hygiene and safety is of utmost importance. The ice machines are designed with removable components for easy cleaning and sanitization, preventing the formation of mold and bacteria. Built-in safeguards, such as water filtration systems, ensure that the ice produced is pure and free from contaminants. Additionally, intelligent design features prevent ice clumping, eliminating potential hazards and ensuring a safe ice consumption experience for customers.Conclusion:With their commitment to sustainability, energy efficiency, and superior ice production, the company's ice machine technology is revolutionizing commercial refrigeration. By combining cutting-edge design and engineering with innovative features, these ice machines offer businesses improved performance, reduced costs, and increased reliability. The seamless integration of automation and connectivity enables better management and resource allocation, providing a more streamlined operation. As the demand for sustainable and efficient refrigeration solutions continues to grow, this company remains at the forefront of innovation, setting new industry standards and meeting the evolving needs of businesses worldwide.

New Plate Freezer Technology Revolutionizes Freezing Process

Title: Revolutionary Plate Freezer Technology Sets New Benchmark in the Commercial Refrigeration IndustrySubtitle: Cutting-Edge Plate Freezer Solution Boosts Efficiency and Productivity for BusinessesIntroduction:In today's fast-paced and competitive business landscape, innovation and efficiency are paramount. Companies across various industries are constantly seeking cutting-edge technologies to streamline their operations and enhance productivity. Introducing a revolutionary Plate Freezer solution, {Company Name}, a leader in the commercial refrigeration industry, is set to redefine the way businesses freeze and store products. By combining their vast expertise and commitment to technological advancements, {Company Name} has developed a game-changing Plate Freezer that offers unparalleled efficiency, reliability, and versatility.The Plate Freezer:Traditionally, companies have used conventional methods to freeze and store various products. However, {Company Name}'s Plate Freezer is a breakthrough solution that transcends these methods, revolutionizing the way businesses freeze and store their goods. This advanced Plate Freezer combines cutting-edge technology with efficient design to offer outstanding performance, ease of use, and flexibility.1. Unmatched Efficiency:{Company Name}'s Plate Freezer sets a new benchmark in freezing efficiency. By utilizing a high-performance refrigeration system, this innovative freezer can rapidly reduce the temperature of products, allowing for quicker freezing cycles. With its state-of-the-art design, the Plate Freezer optimizes heat exchange, maximizing cooling efficiency and significantly reducing the freezing time. This unprecedented efficiency translates into cost savings for businesses, as they can freeze more products in a shorter amount of time.2. Reliable Performance:The reliability of any commercial equipment is crucial for businesses to maintain a seamless production process. Recognizing this, {Company Name} has engineered their Plate Freezer to deliver exceptional performance. By incorporating robust components and advanced control systems, this freezer ensures consistent and reliable freezing results. Its durability and longevity guarantee businesses uninterrupted freezing operations, allowing them to remain competitive and meet customer demands.3. Versatile Design:{Company Name}'s Plate Freezer boasts a versatile design that accommodates a wide range of products. Whether it's seafood, poultry, fruits, or vegetables, this freezer can handle different types of products with ease. Its adjustable settings and customizable freezing parameters enable businesses to adapt to specific freezing requirements, ensuring optimal product quality and longevity. Moreover, the Plate Freezer's modular design allows for easy expansion, providing scalability as businesses grow.Company Overview:With over X years of experience in the commercial refrigeration industry, {Company Name} has established itself as a trusted and respected provider of innovative solutions. Guided by a commitment to excellence and fueled by a passion for technological advancement, {Company Name} has continuously pushed the boundaries to deliver groundbreaking products that transform businesses' refrigeration processes. Their team of skilled engineers and designers blend expertise and creativity to develop solutions tailored to the unique needs of their clients.Conclusion:The commercial refrigeration industry is witnessing a revolution with {Company Name}'s cutting-edge Plate Freezer. This game-changing technology combines unparalleled efficiency, reliable performance, and adaptive design, enabling businesses to streamline their freezing processes and boost productivity. With this innovative solution, {Company Name} once again proves its leadership in the industry and reaffirms its commitment to driving progress and innovation. As businesses across various sectors seek ways to optimize operations and remain competitive, the Plate Freezer from {Company Name} stands tall as a game-changer that propels the industry toward a more efficient and cost-effective future.

Unlock the Power of Evaporative Cooling for Efficient Temperature Control

Title: Advancing Evaporative Cooling Technologies Set to Disrupt the MarketSubtitle: {Company Introduction}'s Revolutionary Solution to Drive Sustainable CoolingIntroduction:In a world grappling with rising temperatures and the urgent need for sustainable cooling solutions, {Company Introduction} is spearheading the development of a groundbreaking technology based on Evaporative Cooling. By harnessing the power of evaporative cooling, the company aims to revolutionize the cooling industry and drive a much-needed shift towards efficient and eco-friendly cooling systems.Body:Evaporative Cooling: A Game-Changing SolutionEvaporative Cooling, also known as swamp cooling, is a natural cooling process that uses the evaporation of water to reduce temperatures. Unlike traditional cooling systems, which rely on refrigerants and compressors that contribute to global warming and escalating energy consumption, evaporative cooling offers an energy-efficient and environmentally-friendly alternative.The principle behind evaporative cooling is simple yet effective. By using water to lower air temperature, this process can provide pleasant cooling effects while consuming significantly less energy. Moreover, evaporative cooling systems are known to improve air quality by increasing moisture levels and filtering out dust particles, making them ideal for arid or dry climates.{Company Introduction}: Shaping the Future of Evaporative Cooling{Company Introduction} recognizes the incredible potential of evaporative cooling and has developed a cutting-edge cooling system that pushes the boundaries of traditional cooling methods. Their solution, which is set to disrupt the market, combines innovative engineering and sustainability principles to create a product like no other.With an unwavering commitment to sustainability, {Company Introduction} has integrated advanced technological features into their evaporative cooling system. By leveraging smart sensors and artificial intelligence algorithms, their cooling solution optimizes water usage based on real-time weather data, ensuring a minimal environmental footprint and maximum efficiency.In addition, {Company Introduction}'s cooling system is designed for versatility and ease of use. The compact and sleek design allows for easy installation in a variety of settings, from homes to commercial buildings. The user-friendly interface provides intuitive controls, allowing for seamless operation and customization.Benefits Beyond Cooling: A Holistic Approach{Company Introduction}'s evaporative cooling system is not limited to providing effective cooling but extends its benefits beyond temperature reduction. The system's enhanced air filtration capabilities significantly improve indoor air quality, thus promoting a healthier and more comfortable environment for occupants.Furthermore, the company's commitment to sustainability is evident in their emphasis on water conservation. By utilizing advanced water management techniques, their cooling system minimizes water consumption while maintaining optimal cooling performance. This approach aligns with global efforts to address water scarcity and emphasizes the company's dedication to responsible resource management.Redefining Efficiency and AffordabilityThe intersection of cutting-edge technology, sustainability, and affordability is where {Company Introduction}'s evaporative cooling system truly shines. With its energy-efficient operation, the system translates into reduced energy bills for end-users. By avoiding the use of refrigerants and compressors, maintenance costs are significantly reduced, ensuring a cost-effective long-term investment.Moreover, in regions where electricity supply may be unreliable or expensive, {Company Introduction}'s cooling system offers a reliable and cost-efficient alternative. This opens up opportunities for access to cooling technology in areas that were previously limited by infrastructure constraints or affordability concerns.Looking Ahead: A Cooler and More Sustainable FutureAs global temperatures continue to rise and the demand for cooling solutions grows, the need for sustainable alternatives becomes increasingly urgent. {Company Introduction} is at the forefront of this movement, leveraging the power of evaporative cooling to reshape the cooling industry.With their state-of-the-art evaporative cooling system, {Company Introduction} is not only redefining efficiency and affordability but also setting new standards for environmentally-conscious cooling solutions. By embracing innovation and sustainability, the company is paving the way for a cooler and more sustainable future.Conclusion:{Company Introduction}'s groundbreaking evaporative cooling system is primed to disrupt the cooling industry. By utilizing the principles of evaporative cooling, their advanced technology not only offers effective temperature reduction but also demonstrates a commitment to sustainability, affordability, and resource management. As the world seeks eco-friendly alternatives, {Company Introduction}'s solution is a shining example of how technology can be harnessed to drive positive change and provide solutions to pressing global challenges.

New Evaporative Condenser Technology Provides Efficient Cooling Solution

Title: Revolutionary Cooling System Revolutionizes Industrial OperationsIntroduction:In recent years, the demand for efficient and sustainable cooling solutions has grown significantly, especially in industries such as power generation, manufacturing, and food processing. Responding to these needs, a leading innovator in the field has introduced the Combined Flow Evaporative Condenser (CFEC), a game-changing cooling system that promises enhanced performance, energy efficiency, and environmental sustainability. The CFEC, developed by a pioneering company [Company Name], redefines industrial cooling, providing solutions that contribute to a greener future while meeting the growing demands of various sectors.I. Improving Efficiency and Performance:[Company Name] has revolutionized the cooling industry with the introduction of the CFEC. This innovative technology offers unparalleled efficiency, ensuring optimal performance for various industrial applications. By combining the principles of a wet cooling tower and a dry condenser, the CFEC effectively enhances the heat exchange process. Through this advanced design, heat transfer efficiency is maximized, resulting in reduced energy consumption and improved overall performance.The CFEC stands out due to its unique design, which optimizes air and water flow patterns within the system. This arrangement minimizes air recirculation, reducing the load on the fans and allowing for better heat dissipation. Additionally, the CFEC incorporates a large heat transfer surface area, efficiently removing excess heat from industrial processes. This technology guarantees consistent performance while ensuring minimal water consumption, a primary concern in water-scarce regions.II. Environmental Sustainability:Addressing the urgent need for more sustainable cooling solutions, the CFEC significantly reduces environmental impact compared to traditional cooling systems. With its efficient operation, the CFEC reduces energy consumption, resulting in lower carbon dioxide emissions. This direct environmental benefit helps industries adhere to stricter environmental regulations and promotes a greener future.Furthermore, the CFEC's water-saving features contribute to water conservation efforts. Employing advanced water management strategies, the system minimizes water loss and optimizes the use of water resources. The CFEC's evaporative process efficiently utilizes available water resources, extracting maximum cooling potential while minimizing wastage. This eco-conscious technology enables industries to reduce their overall water footprint and contribute to sustainable water management practices.III. Versatile Applications:The CFEC's versatility makes it suitable for a wide range of industrial applications. Whether in power plants, manufacturing facilities, or food processing units, this innovative system adapts to varying cooling requirements. The CFEC provides adaptable solutions that cater to specific industries, addressing the unique cooling demands of each sector.Additionally, the CFEC's modular design facilitates easy integration into existing cooling systems. Its compatibility with conventional infrastructure allows for seamless retrofits, reducing overall costs and downtime during installation. This flexibility assists industries in adopting efficient cooling solutions quickly and effectively, without compromising their existing processes.IV. Advancing Industrial Operations:The introduction of the CFEC marks a significant milestone in industrial cooling, taking operations to new heights. By optimizing energy efficiency, minimizing environmental impact, and offering versatile applications, industries can embrace this revolutionary cooling system to gain a competitive edge while reducing their carbon footprint.Conclusion:[Company Name]'s Combined Flow Evaporative Condenser (CFEC) brings a new era of cooling technology to various industries. With its groundbreaking design, the CFEC provides superior efficiency, sustainability, and versatility, redefining the way industrial operations approach cooling processes. In a world demanding sustainable solutions, the CFEC ensures a greener future while enhancing industrial performance, making it a game-changing advancement in cooling technology.

Top Industrial Food Freezers for Efficient Food Storage and Preservation

Industrial Food Freezer Company Expands Offerings to Meet Changing Market NeedsAs the food industry continues to evolve, companies need to adapt to meet changing market demands. Industrial food freezers are no exception, and one company is leading the charge to create innovative solutions for customers across the globe.The industrial food freezer company, which prefers to remain unnamed, has been providing top-of-the-line freezing equipment to companies in a variety of industries for decades. With a focus on creating custom solutions for each customer, the company has earned a reputation as a reliable partner that can be counted on to deliver results.However, as the food industry changes, the demand for new types of freezing equipment has grown. For example, with the rise of plant-based meat alternatives and other new products, companies need freezers that can handle a wider range of products and ingredients.Recognizing this need, the industrial food freezer company has expanded its offerings to include a range of new products that can meet the needs of today's food industry.One of the company's newest products is a custom freezing tunnel that can be used to freeze a variety of different products at high volumes. This tunnel uses advanced technology to quickly and efficiently freeze products, meaning that companies can get their products to market faster than ever before.In addition to the custom freezing tunnel, the company has also developed a range of other innovative products that can be used to freeze a variety of different products. These include spiral freezers, blast freezers, and other specialized equipment that can be customized to meet the needs of each customer.One of the key advantages of working with the industrial food freezer company is its focus on customization. Rather than offering one-size-fits-all products, the company works closely with each customer to understand their unique needs and develop a custom solution that meets those needs exactly.This approach has helped the company build a strong reputation among customers who value personalized service and attention to detail. By working closely with customers, the company is able to create solutions that not only meet their needs today, but can also adapt to changing market demands in the future.Of course, the industrial food freezer company's commitment to quality doesn't stop at the design phase. The company also offers extensive support to its customers, including installation, training, and ongoing maintenance and support.This commitment to customer service has helped the industrial food freezer company build strong, long-lasting relationships with customers around the world. Whether a customer is looking for a single piece of equipment or a comprehensive freezing system, the company is dedicated to providing the highest level of service and support.As the food industry continues to change and evolve, companies need partners they can trust to help them stay ahead of the curve. With its focus on customization, innovation, and customer service, the industrial food freezer company is well-positioned to help customers meet their freezing needs today and in the future.

Discover the Latest Advancements in Stainless Steel Plate Heat Exchangers

Title: Advanced Stainless Steel 316 Plate Heat Exchanger Revolutionizes Heat Transfer TechnologyIntroductionThe purpose of this article is to shed light on the innovative Stainless Steel 316 Plate Heat Exchanger, developed by a leading company in the heat transfer technology. This cutting-edge product promises to revolutionize heat exchange processes across various industrial sectors, offering unparalleled efficiency and reliability in diverse applications. With its exceptional corrosion resistance and impressive heat transfer capacity, the Stainless Steel 316 Plate Heat Exchanger is set to transform the way industries handle thermal management.BackgroundThe company behind this groundbreaking innovation has a rich history of producing high-quality heat exchangers that meet the specific needs of various industries. With extensive research and development capabilities, they consistently redefine technological boundaries. Committed to promoting sustainable practices, their products are designed to enhance energy efficiency, reduce operational costs, and minimize environmental impacts. Through continuous improvement and customer-centric approach, this company has become renowned for its production of state-of-the-art heat exchangers.The New Era of Heat Transfer: Stainless Steel 316 Plate Heat ExchangerThe Stainless Steel 316 Plate Heat Exchanger marks a significant milestone in heat transfer technology. This advanced equipment leverages the exceptional properties of stainless steel, particularly the corrosion-resistant grade 316, to optimize heat exchange efficiency and longevity. The structure of the heat exchanger consists of a series of stacked plates, allowing for increased surface area for heat transfer while minimizing pressure drop.Corrosion Resistance for Uncompromised PerformanceThe primary advantage of the Stainless Steel 316 Plate Heat Exchanger is its remarkable resistance to corrosion. This characteristic makes it ideal for applications in aggressive process environments, including the chemical, pharmaceutical, oil and gas, and food and beverage industries. Its resistance to chemicals, acids, and chlorides ensures longevity and reliability even in highly corrosive conditions. This extends the lifespan of the heat exchanger, resulting in reduced maintenance costs and improved overall operational efficiency.Enhanced Heat Transfer EfficiencyThe unique plate design of the Stainless Steel 316 Plate Heat Exchanger allows for impressive heat transfer rates. The plates are engineered to maximize the contact surface area for efficient thermal exchange, resulting in rapid heat dissipation or heat absorption. This increased efficiency not only enhances overall performance but also allows for more compact system designs, saving valuable space and reducing installation costs.Versatile ApplicationsThe versatility of the Stainless Steel 316 Plate Heat Exchanger is a key characteristic that sets it apart from traditional heat exchangers. The compact design and high heat transfer capacity make it suitable for a wide range of applications. From HVAC systems to industrial process cooling, waste heat recovery, and refrigeration, this heat exchanger excels in diverse environments. Its ability to withstand extreme temperatures and pressures ensures that it can meet the most demanding requirements of various industries.Environmental BenefitsBy promoting energy efficiency and reducing carbon footprints, the Stainless Steel 316 Plate Heat Exchanger plays a vital role in sustainable heat management. The optimized heat transfer rates enable industries to reduce their energy consumption and, in turn, decrease greenhouse gas emissions. Additionally, the durability and longevity of the heat exchanger contribute to a more sustainable approach, minimizing waste and the need for frequent replacements.ConclusionThe Stainless Steel 316 Plate Heat Exchanger is set to transform heat transfer technology, providing industries with an innovative solution to their thermal management challenges. With its impressive corrosion resistance, enhanced heat transfer efficiency, versatility, and environmental benefits, this advanced heat exchanger is poised to improve operational performance, decrease costs, and pave the way for a more sustainable future. The company's ongoing commitment to research and development showcases their dedication to innovation and customer satisfaction, ensuring that they remain at the forefront of heat transfer technology.

Ultimate Guide to Efficient and Reliable Ice Making Machines: Exploring the Latest Ice Production Technologies

Innovative Ice Making Machine Set to Revolutionize the IndustryIce is a necessity in many industries. Whether it's for food service, healthcare, or entertainment, having a steady and reliable supply of ice is crucial. With that in mind, a new player in the market is set to redefine the ice-making industry with its cutting-edge machine.Introducing the groundbreaking ice making machine, a product developed by a leading company in the field. The company, with over two decades of experience in manufacturing refrigeration equipment, has consistently demonstrated its commitment to excellence and customer satisfaction. Their innovative products have garnered accolades from industry experts and customers alike.This new ice making machine is designed to be the ultimate solution for businesses that rely on ice production. Featuring state-of-the-art technology, it boasts advanced functionality and unparalleled efficiency. The machine's cutting-edge features, combined with its sleek and modern design, make it a standout in the market.One of the key features of this ice making machine is its impressive production capacity. With the ability to produce up to X pounds of ice per day, it ensures a constant supply for any business, regardless of its size or demands. The machine also offers customizable options, allowing users to adjust the ice shape and size to suit their specific needs.Moreover, this ice making machine is equipped with high-end technology that optimizes energy consumption, reducing both electricity costs and environmental impact. Its advanced control system allows for efficient ice production, ensuring minimal water and energy waste. This eco-friendly aspect sets it apart from other machines in the market, making it a truly sustainable choice.Safety is another paramount feature of this ice making machine. With its smart sensors and automated processes, it ensures that ice production is always hygienic and contaminant-free. The machine's self-cleaning system eliminates the need for manual intervention, saving time and effort for the users. Additionally, it is built with high-quality materials that are resistant to corrosion, ensuring long-lasting performance.The company behind this ice making machine also offers comprehensive after-sales support services. Recognizing the importance of reliable customer service, they provide prompt assistance and maintenance to ensure that the product operates at its optimum performance. This commitment to customer satisfaction sets them apart from their competitors in the industry.The versatility of this ice making machine makes it suitable for a wide range of applications. Whether it's for hotels, restaurants, hospitals, or event venues, the machine’s adaptability is unparalleled. Its compact design allows for easy installation and integration into existing systems, making it a hassle-free choice for businesses.Industry experts have already taken notice of this groundbreaking product. Renowned for its excellence, the company has received numerous awards, and this innovative ice making machine is expected to be no different. The machine's advanced features, impressive production capacity, and eco-friendly design are sure to make it a game-changer in the ice-making industry.In conclusion, this new ice making machine, developed by a leading company in the field, is set to revolutionize the industry. With its state-of-the-art technology, efficiency, and reliability, it is poised to become the go-to choice for businesses in need of a steady and sustainable supply of ice. As the market eagerly awaits its release, it's clear that this innovative product will redefine the standards of ice production.

Efficient Air Cooled Screw Chiller Offers Cooling Solutions for Industrial Applications

Title: New Air-Cooled Screw Chiller Revolutionizes Cooling SolutionsIntroduction:The cooling industry is witnessing a remarkable advancement with the introduction of the latest Air-Cooled Screw Chiller. Designed to deliver optimal cooling performance, energy efficiency, and enhanced sustainability, this innovative technology is set to revolutionize the way various industries tackle their cooling requirements. In this news article, we will delve into the key features and benefits of this groundbreaking solution, while also exploring the company's commitment to providing exceptional cooling solutions.I. Energy Efficiency and Sustainability:The new Air-Cooled Screw Chiller is designed to significantly reduce energy consumption, making it an environmentally friendly choice for businesses across multiple sectors. With advanced technologies, such as variable speed controls and intelligent monitoring systems, it maximizes energy efficiency while ensuring optimal cooling performance. This chiller embraces the concept of sustainability by utilizing eco-friendly refrigerants and reducing overall carbon footprint. By investing in this cutting-edge solution, businesses can not only save costs but also contribute to a greener future.II. Smart Control and Monitoring Systems:Ensuring precise temperature control and efficient operation, the Air-Cooled Screw Chiller incorporates intelligent control and monitoring systems. These systems provide operators with real-time data, enabling them to make informed decisions and optimize the chiller's performance. The user-friendly interface allows for easy access to crucial information, allowing businesses to monitor energy consumption, troubleshoot potential issues, and schedule maintenance efficiently. With remote monitoring capabilities, users can manage their chiller operations from anywhere, further enhancing operational convenience and reducing downtime.III. Enhanced Reliability and Flexibility:Built with high-quality components and state-of-the-art technology, the Air-Cooled Screw Chiller is designed to deliver exceptional reliability and durability. The robust construction and innovative features ensure continuous operation, even in harsh environmental conditions. With enhanced load flexibility, this chiller adapts to varying cooling requirements efficiently, making it suitable for a wide range of applications across industries, such as data centers, manufacturing plants, commercial buildings, and more. Whether it is a small or large-scale cooling demand, this chiller offers tailored solutions to meet specific needs.IV. Easy Installation and Maintenance:The Air-Cooled Screw Chiller is engineered with ease of installation and maintenance in mind. Its compact design and modular construction allow for seamless integration into existing infrastructures, minimizing installation time and costs. The user-friendly design also simplifies routine maintenance tasks, ensuring minimal downtime and maximum operational efficiency. With readily accessible parts and comprehensive service support, businesses can achieve hassle-free maintenance, reducing operational disruptions and optimizing overall productivity.V. Company Commitment to Excellence:The company behind this groundbreaking Air-Cooled Screw Chiller has a rich history of delivering innovative and reliable cooling solutions to global markets. With a focus on customer satisfaction, they pride themselves on providing exceptional technical support and after-sales service. The company's commitment to research and development ensures that their products are not only at the cutting edge of technology but also compliant with industry standards and regulations. With a vast network of authorized distributors and service centers, customers can rely on their expertise for installation, maintenance, and upgrades.Conclusion:The introduction of the new Air-Cooled Screw Chiller marks a significant milestone in the cooling industry. Its energy efficiency, sustainability, reliability, and flexibility set a new benchmark for cooling solutions. With improved control systems, easy installation, and comprehensive service support, businesses can achieve optimal cooling performance while reducing operational costs and environmental impact. As the company behind this innovative product continues to pioneer cooling technologies, customers can expect more breakthroughs in the future, revolutionizing the way industries approach their cooling needs.

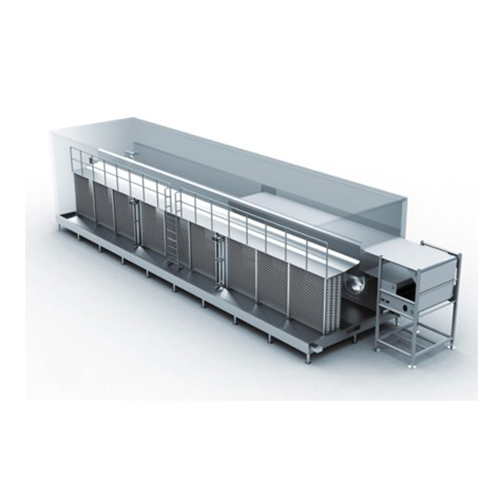

Innovative Tunnel Freezer Technology for Faster and Efficient Freezing

Fluidized Flow Bed Tunnel Freezer Offers Efficient and Cost-Effective Freezing SolutionA new innovative line of freezer technology has been introduced by a leading global freezing equipment manufacturer. The company, known for its high-quality and cost-effective equipment, has developed the Fluidized Flow Bed Tunnel Freezer to meet the needs of food manufacturers and processors in the market. The Fluidized Flow Bed Tunnel Freezer is a great solution that has been received positively by the industry, and its innovative features are sure to make freezing operations seamless, efficient and cost-effective.The Fluidized Flow Bed Tunnel Freezer operates with an innovative technology called fluidization. Frozen food products are suspended by a bed of air leaving no contact with the cooling plates. This allows for even cooling and freezing without product damage, resulting in better product quality and appearance. The fluidization process creates a bed of cold air that is used to cool the products, providing an efficient and uniform freezing process.Moreover, The Fluidized Flow Bed Tunnel Freezer is designed to be versatile, efficient, and cost-effective. With adjustable fan speeds and air direction control, manufacturers and processors can customize the system to fit any product’s freezing requirements. In addition, the fluidized flow bed system creates a uniform temperature in the freezer tunnel, leading to more consistent production quality and quantity.According to the company, the Fluidized Flow Bed Tunnel Freezer is designed to improve production times while reducing energy consumption and maintenance costs. This innovative freezer design offers lower operating costs, making it a cost-effective solution for food manufacturers looking for a high-quality freezer system that is both efficient and reliable.Food manufacturers who have tested the Fluidized Flow Bed Tunnel Freezer have reported a significant increase in production capacity due to reduced cycle times. In addition, they noted that the system provides faster freezing times without affecting product quality. The fluidization process also ensures a uniform product quality, making it ideal for sensitive and delicate products such as ready-to-eat foods, seafood, and pastries.The innovative design of the Fluidized Flow Bed Tunnel Freezer means that there is minimal maintenance required. The system requires fewer parts to ensure its functionality, reducing the chances of breakdown due to mechanical failure. This reduces the downtime for maintenance and repairs, ensuring that the production line remains active for longer periods.The Fluidized Flow Bed Tunnel Freezer is not only an efficient and cost-effective solution for food manufacturers, but it is also an environmentally friendly choice. The system operates with eco-friendly refrigerants, reducing the environmental impact and lowering the carbon footprint of the freezing process.In summary, the Fluidized Flow Bed Tunnel Freezer has been designed to cater to the needs of the food processing industry by offering a cost-effective, efficient, and reliable solution to freezing operations. With its innovative features and environment-friendly design, the system is guaranteed to improve production capacity while reducing energy costs, making it an ideal investment for food manufacturers looking to enhance their operations.